1. Introduction

The impact of a liquid drop on a solid target has been extensively studied (Yarin Reference Yarin2006; Josserand & Thoroddsen Reference Josserand and Thoroddsen2016; Yarin, Roisman & Tropea Reference Yarin, Roisman and Tropea2017) since Worthington's pioneering observations (Worthington Reference Worthington1877). The dynamics of the spreading liquid can now be described using analytical expressions once the drop touches the substrate (Gordillo, Riboux & Quintero Reference Gordillo, Riboux and Quintero2019). The initial stage of spreading is governed by inertia so that the wetted radius follows Wagner's theorem (Riboux & Gordillo Reference Riboux and Gordillo2014). Later, viscous and capillary forces oppose the outwards motion and ultimately balance the initial inertia as the maximal radius is reached (Laan et al. Reference Laan, de Bruin, Bartolo, Josserand and Bonn2014; Wildeman et al. Reference Wildeman, Visser, Sun and Lohse2016). Yet, before spreading starts, the air trapped between the falling drop and the substrate must drain for contact to occur. This phase, during which the drop levitates on an air cushion, can affect the outcome of impact as revealed by the dramatic influence of ambient pressure on splashing (Xu, Zhang & Nagel Reference Xu, Zhang and Nagel2005; Driscoll & Nagel Reference Driscoll and Nagel2011). This levitation phase can even dominate and last during the whole impact for low impact velocities (Kolinski, Mahadevan & Rubinstein Reference Kolinski, Mahadevan and Rubinstein2014a). This holds even more when the substrate is heated far above the boiling point of the liquid, as then the impacting drop is separated from the substrate by a cushion of its own vapour, a situation called the dynamic Leidenfrost effect (Tran et al. Reference Tran, Staat, Prosperetti, Sun and Lohse2012).

The Leidenfrost effect (Leidenfrost Reference Leidenfrost1756; Quéré Reference Quéré2013) has received a lot of attention owing to its relevance in heat transfer applications such as spray cooling (Kim Reference Kim2007; Breitenbach, Roisman & Tropea Reference Breitenbach, Roisman and Tropea2018), the cooling of fuel rods in case of a nuclear incident (Hamdan, Kim & Moon Reference Hamdan, Kim and Moon2015) or spray combustion (Moreira, Moita & Panao Reference Moreira, Moita and Panao2010). As the presence of gas between the liquid and the solid dramatically reduces the heat flux, phase diagrams distinguishing levitation and contact behaviours have been obtained for many liquid–solid combinations based on side-view imaging (Yao & Cai Reference Yao and Cai1988; Bernardin & Mudawar Reference Bernardin and Mudawar2004) and, more recently, on the direct bottom-view observation of contact (Tran et al. Reference Tran, Staat, Prosperetti, Sun and Lohse2012; Staat et al. Reference Staat, Tran, Geerdink, Riboux, Sun, Gordillo and Lohse2015; Shirota et al. Reference Shirota, van Limbeek, Sun, Prosperetti and Lohse2016). Understanding the dynamics of the air and vapour film (together referred to as gas from now on) trapped at impact on superheated substrates is thus key to predicting the heat transfer.

When the liquid and the solid are both at ambient temperature, the drainage of the air film trapped between the falling drop and the substrate has been thoroughly investigated. In this situation, that we call an isothermal impact, the pressure buildup under the drop results in the formation of a dimple whose edge is marked by a localized region of high curvature, called the neck (Mandre, Mani & Brenner Reference Mandre, Mani and Brenner2009; Hicks & Purvis Reference Hicks and Purvis2010; Mani, Mandre & Brenner Reference Mani, Mandre and Brenner2010; Bouwhuis et al. Reference Bouwhuis, van der Veen, Tran, Keij, Winkels, Peters, van der Meer, Sun, Snoeijer and Lohse2012). This region eventually moves downwards, leading either to the wetting of the substrate and the entrapment of an air bubble (Chandra & Avedisian Reference Chandra and Avedisian1991; Thoroddsen et al. Reference Thoroddsen, Etoh, Takehara, Ootsuka and Hatsuki2005), or, for low enough impact velocities and sufficiently smooth substrates, to the creation of a relatively flat air film that can enable drop bouncing (Kolinski et al. Reference Kolinski, Mahadevan and Rubinstein2014a). In the latter case, the dimple and neck have a fixed radial position and height as the liquid spreads (Kolinski et al. Reference Kolinski, Rubinstein, Mandre, Brenner, Weitz and Mahadevan2012; Kolinski, Mahadevan & Rubinstein Reference Kolinski, Mahadevan and Rubinstein2014b). For impacts on superheated substrates, however, it is yet unclear how evaporation contributes to the evolution of the gas film, although it is already known that the dimple and neck structure also appears (Shirota et al. Reference Shirota, van Limbeek, Sun, Prosperetti and Lohse2016).

In this article, we aim to disentangle the effects of gas drainage and vapour generation on the short-time drop impact dynamics to provide insight into the transition from drop levitation to contact. In order to do so, we probed the dynamics of the gas layer squeezed between the liquid and the substrate at impact and monitored the failure of the gas film. We observed hitherto unreported vertical oscillations of the drop bottom interface, specific to superheated conditions, that can trigger contact events. We thus seek to understand the role of these oscillations on the transition towards the dynamic Leidenfrost effect. The experimental set-up and procedure are detailed in § 2. In § 3, we discuss the evolution of the film shape at short times and the influence of surface temperature on its characteristic features. We also report the measurements of the minimum thickness at short times and provide a model to account for them. In § 4, the transition from levitation to contact is discussed, based on identifying the type of collapse of the gas layer in the parameter space spanned by the surface temperature and the impact velocity. Finally, we model the vertical oscillations of the drop's base and discuss their role in the transition towards the dynamic Leidenfrost effect. The paper ends with conclusions and an outlook (§ 5).

2. Experimental set-up and procedure

Our experiments, sketched in figure 1, consist of impacting ethanol drops (with density ![]() $\rho_l$, viscosity

$\rho_l$, viscosity ![]() $\eta_l$ and surface tension

$\eta_l$ and surface tension ![]() $\gamma$) on an optically smooth sapphire disk. We chose this liquid–solid combination as (i) it allows us to neglect vapour cooling effects during impact and (ii) the excellent thermal conductivity of sapphire (

$\gamma$) on an optically smooth sapphire disk. We chose this liquid–solid combination as (i) it allows us to neglect vapour cooling effects during impact and (ii) the excellent thermal conductivity of sapphire (![]() $k_s = 35$ W K

$k_s = 35$ W K![]() $^{-1}$ m

$^{-1}$ m![]() $^{-1}$) approximates isothermal substrate conditions (Van Limbeek et al. Reference Van Limbeek, Shirota, Sleutel, Sun, Prosperetti and Lohse2016, Reference Van Limbeek, Schaarsberg, Sobac, Rednikov, Sun, Colinet and Lohse2017). The sapphire substrate is coupled to a glass dove prism using silicone oil and mounted in an aluminium heating block. The substrate temperature

$^{-1}$) approximates isothermal substrate conditions (Van Limbeek et al. Reference Van Limbeek, Shirota, Sleutel, Sun, Prosperetti and Lohse2016, Reference Van Limbeek, Schaarsberg, Sobac, Rednikov, Sun, Colinet and Lohse2017). The sapphire substrate is coupled to a glass dove prism using silicone oil and mounted in an aluminium heating block. The substrate temperature ![]() $T_s$ is set to a fixed value between

$T_s$ is set to a fixed value between ![]() $105\,^\circ$C and

$105\,^\circ$C and ![]() $270\,^\circ$C using a proportional-integral-derivative controller, and measured with an external surface probe. From this, we deduce the superheat

$270\,^\circ$C using a proportional-integral-derivative controller, and measured with an external surface probe. From this, we deduce the superheat ![]() $\Delta T = T_s - T_b$, where

$\Delta T = T_s - T_b$, where ![]() $T_b = 78\,^\circ$C is the boiling temperature of ethanol. Drops with radius

$T_b = 78\,^\circ$C is the boiling temperature of ethanol. Drops with radius ![]() $R = 1.0 \pm 0.1$ mm are released from a calibrated needle, whose height is adjusted to obtain impact velocities

$R = 1.0 \pm 0.1$ mm are released from a calibrated needle, whose height is adjusted to obtain impact velocities ![]() $U$ ranging from 0.3 to 1.2 m s

$U$ ranging from 0.3 to 1.2 m s![]() $^{-1}$. The chosen drop radii and impact velocities correspond to a Reynolds number

$^{-1}$. The chosen drop radii and impact velocities correspond to a Reynolds number ![]() ${\textit {Re}} = \rho _l R U/\eta _l$ and an Ohnesorge number

${\textit {Re}} = \rho _l R U/\eta _l$ and an Ohnesorge number ![]() ${\textit {Oh}} = \eta _l/\sqrt {\rho _l R \gamma }$, with typical values of 500 and 0.01, respectively, i.e. initially viscous effects can be neglected compared with inertia and capillarity. The Weber number

${\textit {Oh}} = \eta _l/\sqrt {\rho _l R \gamma }$, with typical values of 500 and 0.01, respectively, i.e. initially viscous effects can be neglected compared with inertia and capillarity. The Weber number ![]() ${\textit {We}} = \rho _l RU^2/\gamma$, ranging from 3 to 50, further indicates that experiments are conducted in the inertial regime, as evidenced by Bouwhuis et al. (Reference Bouwhuis, van der Veen, Tran, Keij, Winkels, Peters, van der Meer, Sun, Snoeijer and Lohse2012) in their study of dimple formation. Table 1 gives an overview of the properties of the liquid and of the two components of the gas phase: air (with ambient temperature

${\textit {We}} = \rho _l RU^2/\gamma$, ranging from 3 to 50, further indicates that experiments are conducted in the inertial regime, as evidenced by Bouwhuis et al. (Reference Bouwhuis, van der Veen, Tran, Keij, Winkels, Peters, van der Meer, Sun, Snoeijer and Lohse2012) in their study of dimple formation. Table 1 gives an overview of the properties of the liquid and of the two components of the gas phase: air (with ambient temperature ![]() $T_a$) and ethanol vapour. Note that the material properties of the fluids are temperature dependent (see Appendix A) and the temperature at which they should be evaluated will be discussed throughout the manuscript.

$T_a$) and ethanol vapour. Note that the material properties of the fluids are temperature dependent (see Appendix A) and the temperature at which they should be evaluated will be discussed throughout the manuscript.

Figure 1. Ethanol drops with equilibrium radius ![]() $R$ and velocity

$R$ and velocity ![]() $U$ impact a heated sapphire substrate with temperature

$U$ impact a heated sapphire substrate with temperature ![]() $T_s$. We record side views and use reflection interference (RI) and total internal reflection (TIR) imaging to measure the thickness of the gas film squeezed between the liquid and the solid with three synchronized high-speed cameras. We define in the sketch the dimple and neck height,

$T_s$. We record side views and use reflection interference (RI) and total internal reflection (TIR) imaging to measure the thickness of the gas film squeezed between the liquid and the solid with three synchronized high-speed cameras. We define in the sketch the dimple and neck height, ![]() $h_d$ and

$h_d$ and ![]() $h_n$, respectively, as well as the radial extent of the neck region

$h_n$, respectively, as well as the radial extent of the neck region ![]() $\ell$ (sketch not to scale).

$\ell$ (sketch not to scale).

Table 1. Physical properties of ethanol in the liquid (l) and vapour (v) phase and of air.

We study the impact dynamics using three synchronized high-speed cameras to obtain side views and interferometric measurements of the gas film (figure 1). We record side views at 20 000 frames per second (Photron Fastcam SA1.1) from which we determine the drop radius ![]() $R$ and the impact velocity

$R$ and the impact velocity ![]() $U$. We measure the gas film thickness profile by coupling two interferometry techniques that have been successfully applied in the context of drop impact: single-wavelength reflection interference (RI) (Driscoll & Nagel Reference Driscoll and Nagel2011; Li & Thoroddsen Reference Li and Thoroddsen2015; Staat et al. Reference Staat, Tran, Geerdink, Riboux, Sun, Gordillo and Lohse2015) and total internal reflection (TIR) imaging (Kolinski et al. Reference Kolinski, Rubinstein, Mandre, Brenner, Weitz and Mahadevan2012; Shirota et al. Reference Shirota, van Limbeek, Sun, Prosperetti and Lohse2016). Simultaneously using these two techniques allows us to realize the benefits of both of them: RI enables relative thickness measurements of thin films up to tens of micrometres while TIR imaging provides an absolute information on the evanescent length scale of the order of 100 nm. The combination of both techniques gives access to the absolute thickness of the entire profile of the gas layer during drop impact.

$U$. We measure the gas film thickness profile by coupling two interferometry techniques that have been successfully applied in the context of drop impact: single-wavelength reflection interference (RI) (Driscoll & Nagel Reference Driscoll and Nagel2011; Li & Thoroddsen Reference Li and Thoroddsen2015; Staat et al. Reference Staat, Tran, Geerdink, Riboux, Sun, Gordillo and Lohse2015) and total internal reflection (TIR) imaging (Kolinski et al. Reference Kolinski, Rubinstein, Mandre, Brenner, Weitz and Mahadevan2012; Shirota et al. Reference Shirota, van Limbeek, Sun, Prosperetti and Lohse2016). Simultaneously using these two techniques allows us to realize the benefits of both of them: RI enables relative thickness measurements of thin films up to tens of micrometres while TIR imaging provides an absolute information on the evanescent length scale of the order of 100 nm. The combination of both techniques gives access to the absolute thickness of the entire profile of the gas layer during drop impact.

We implement these two techniques simultaneously by expanding a diode laser spot with wavelength ![]() $\lambda = 643$ nm into a collimated beam that we split into two optical paths leading to the substrate. The beam used for RI imaging is introduced through the bottom face of the dove prism at a slight angle to only observe interferences generated by reflections at the top of the substrate and the bottom of the drop. The interference patterns are composed of dark and bright fringes that we image using a long distance microscope (Navitar telecentric 12

$\lambda = 643$ nm into a collimated beam that we split into two optical paths leading to the substrate. The beam used for RI imaging is introduced through the bottom face of the dove prism at a slight angle to only observe interferences generated by reflections at the top of the substrate and the bottom of the drop. The interference patterns are composed of dark and bright fringes that we image using a long distance microscope (Navitar telecentric 12![]() $\times$) mounted on a high-speed camera (Photron SA-Z) to obtain a typical resolution of 8

$\times$) mounted on a high-speed camera (Photron SA-Z) to obtain a typical resolution of 8 ![]() $\mathrm {\mu }$m px

$\mathrm {\mu }$m px![]() $^{-1}$ at a frame rate of 700 000 frames per second. The TIR beam is p-polarized and introduced through one of the sloped faces of the prism so that it undergoes TIR at the top of the substrate. The interaction of the emitted evanescent wave and the impinging drop results in a decrease of the reflected intensity that enables the measurement of the film thickness. When the drop touches the surface, light transmits through the liquid creating a sharp change in grey scale intensity that allows us to distinguish wetted from dry areas. The resulting images are recorded at 225 000 frames per second (Photron Nova S12) with a long distance microscope with resolution

$^{-1}$ at a frame rate of 700 000 frames per second. The TIR beam is p-polarized and introduced through one of the sloped faces of the prism so that it undergoes TIR at the top of the substrate. The interaction of the emitted evanescent wave and the impinging drop results in a decrease of the reflected intensity that enables the measurement of the film thickness. When the drop touches the surface, light transmits through the liquid creating a sharp change in grey scale intensity that allows us to distinguish wetted from dry areas. The resulting images are recorded at 225 000 frames per second (Photron Nova S12) with a long distance microscope with resolution ![]() $10\,\mathrm {\mu }$m px

$10\,\mathrm {\mu }$m px![]() $^{-1}$. The details of image processing and calibration of interferometric measurements are further discussed in Appendix B.

$^{-1}$. The details of image processing and calibration of interferometric measurements are further discussed in Appendix B.

3. Short-time dynamics of the gas film

Side views of the impact event of an ethanol drop in the dynamic Leidenfrost regime are presented in figure 2(a) (![]() $U = 0.5$ m s

$U = 0.5$ m s![]() $^{-1}$,

$^{-1}$, ![]() ${\textit {We}} = 9.9$ and

${\textit {We}} = 9.9$ and ![]() $T_s = 164\,^\circ$C). The impinging liquid spreads, recoils and finally detaches from the substrate after a time of the order of 10 ms. This time, that we call the rebound time, is set by the inertio-capillary time scale

$T_s = 164\,^\circ$C). The impinging liquid spreads, recoils and finally detaches from the substrate after a time of the order of 10 ms. This time, that we call the rebound time, is set by the inertio-capillary time scale ![]() $\tau _c = \sqrt {\rho _lR^3/\gamma }$ (Richard, Clanet & Quéré Reference Richard, Clanet and Quéré2002; Biance et al. Reference Biance, Chevy, Clanet, Lagubeau and Quéré2006). Here, we define the origin of time (

$\tau _c = \sqrt {\rho _lR^3/\gamma }$ (Richard, Clanet & Quéré Reference Richard, Clanet and Quéré2002; Biance et al. Reference Biance, Chevy, Clanet, Lagubeau and Quéré2006). Here, we define the origin of time (![]() $t=0$) as the time of the first frame where the drop enters within the evanescent length scale. We focus on the dynamics of the gas film squeezed between the liquid and the hot substrate at the first instant of impact, that is for

$t=0$) as the time of the first frame where the drop enters within the evanescent length scale. We focus on the dynamics of the gas film squeezed between the liquid and the hot substrate at the first instant of impact, that is for ![]() $0 < t < \tau _i$ where

$0 < t < \tau _i$ where ![]() $\tau _i = R/U$ is the inertial time scale. For a drop with radius 1 mm impacting at 1 m s

$\tau _i = R/U$ is the inertial time scale. For a drop with radius 1 mm impacting at 1 m s![]() $^{-1}$, this inertial time is

$^{-1}$, this inertial time is ![]() $\tau _i = 1$ ms and therefore much shorter than the inertio-capillary time

$\tau _i = 1$ ms and therefore much shorter than the inertio-capillary time ![]() $\tau _c \approx 10$ ms.

$\tau _c \approx 10$ ms.

Figure 2. (a) Side-view snapshots of the impact of an ethanol drop (![]() $R = 1.1$ mm,

$R = 1.1$ mm, ![]() $U = 0.5$ m s

$U = 0.5$ m s![]() $^{-1}$ and

$^{-1}$ and ![]() ${\textit {We}} = 9.9$) on a substrate heated at

${\textit {We}} = 9.9$) on a substrate heated at ![]() $T_s = 164\,^\circ$C. The liquid detaches after 18.1 ms. Note that the side view is recorded at a slight angle from the horizontal. (b) Short-time TIR snapshots taken during the impact pictured in (a). The origin of time (

$T_s = 164\,^\circ$C. The liquid detaches after 18.1 ms. Note that the side view is recorded at a slight angle from the horizontal. (b) Short-time TIR snapshots taken during the impact pictured in (a). The origin of time (![]() $t=0$) is chosen as the first frame where the liquid enters within the evanescent length scale. The original grey scale image and reconstructed height field with a cutoff height of 800 nm are shown. (c) Synchronized RI snapshots showing approximately one fourth of the drop's bottom interface. Videos (S1–S2) are in the supplementary material available at https://doi.org/10.1017/jfm.2021.843.

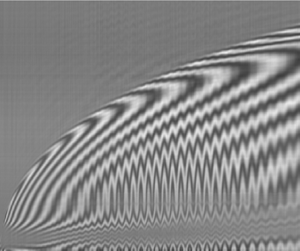

$t=0$) is chosen as the first frame where the liquid enters within the evanescent length scale. The original grey scale image and reconstructed height field with a cutoff height of 800 nm are shown. (c) Synchronized RI snapshots showing approximately one fourth of the drop's bottom interface. Videos (S1–S2) are in the supplementary material available at https://doi.org/10.1017/jfm.2021.843.

3.1. Phenomenology

3.1.1. Sequence of events

In figure 2(b,c), we present synchronized TIR (figure 2b) and RI (figure 2c) images recorded during the first instants of the impact presented in figure 2(a). The TIR snapshots combine the original grey scale image and the calculated height field colour map. The liquid first enters within the evanescent length scale as a faint ring (![]() $t = 0.018$,ms). This ring expands as its height decreases, indicating that the liquid comes closer to the substrate as it starts spreading (

$t = 0.018$,ms). This ring expands as its height decreases, indicating that the liquid comes closer to the substrate as it starts spreading (![]() $t = 0.035$ ms). The full film profile can be inferred by combining the information extracted from TIR with the axisymmetric interference patterns observed in RI images. The brightest fringes are localized at the same radial position as the TIR ring evidencing the region closest to the substrate which is called the neck. The liquid–air interface displays a dimple shape, sketched in the inset, as already observed in both isothermal and superheated conditions (Shirota et al. Reference Shirota, van Limbeek, Sun, Prosperetti and Lohse2016). Eventually, the whole bottom interface of the drop moves away from the substrate and escapes from the TIR measurement range (

$t = 0.035$ ms). The full film profile can be inferred by combining the information extracted from TIR with the axisymmetric interference patterns observed in RI images. The brightest fringes are localized at the same radial position as the TIR ring evidencing the region closest to the substrate which is called the neck. The liquid–air interface displays a dimple shape, sketched in the inset, as already observed in both isothermal and superheated conditions (Shirota et al. Reference Shirota, van Limbeek, Sun, Prosperetti and Lohse2016). Eventually, the whole bottom interface of the drop moves away from the substrate and escapes from the TIR measurement range (![]() $t = 0.28$ ms) while we continue to observe the spreading liquid as the RI fringe pattern remains visible.

$t = 0.28$ ms) while we continue to observe the spreading liquid as the RI fringe pattern remains visible.

Combining TIR and RI, we are able to visualize the dynamics of the whole gas layer and to compare them with their isothermal counterpart. We azimuthally average each RI and TIR snapshot and stack the one-dimensional information obtained at each instant in space–time two-dimensional graphs (figures 3(a) and 3(b)). From this representation, we are able to distinguish three phases in the early evolution of the squeezed film:

(i) The initial approach during which the liquid–gas interface first deforms, creating the central dimple bordered by a region of high curvature (see the first profile of the liquid–gas interface,

$\Delta t = 0$ ms, in figure 3c). This region, which is called the neck region, moves down and outwards until the minimum thickness is reached at the neck, here at

$\Delta t = 0$ ms, in figure 3c). This region, which is called the neck region, moves down and outwards until the minimum thickness is reached at the neck, here at  $t = 0.031$ ms, marking the end of this first phase. During this initial phase, the motion of the liquid–gas interface is qualitatively similar to that reported in the absence of substrate heating (Mandre et al. Reference Mandre, Mani and Brenner2009; Hicks & Purvis Reference Hicks and Purvis2010; Mani et al. Reference Mani, Mandre and Brenner2010; Bouwhuis et al. Reference Bouwhuis, van der Veen, Tran, Keij, Winkels, Peters, van der Meer, Sun, Snoeijer and Lohse2012).

$t = 0.031$ ms, marking the end of this first phase. During this initial phase, the motion of the liquid–gas interface is qualitatively similar to that reported in the absence of substrate heating (Mandre et al. Reference Mandre, Mani and Brenner2009; Hicks & Purvis Reference Hicks and Purvis2010; Mani et al. Reference Mani, Mandre and Brenner2010; Bouwhuis et al. Reference Bouwhuis, van der Veen, Tran, Keij, Winkels, Peters, van der Meer, Sun, Snoeijer and Lohse2012).(ii) A second phase, for

$0.031 < t<0.4$ ms, in which the centre of the dimple and the neck have markedly different vertical motion. The thickness at the centre (

$0.031 < t<0.4$ ms, in which the centre of the dimple and the neck have markedly different vertical motion. The thickness at the centre ( $r=0$) is constant, as evidenced by the absence of crossings between iso-height lines (i.e. fringes) and the centreline in figure 3(a). In the same time interval, the neck thickness increases, as shown by the TIR data (figure 3b) and by the multiple crossings between the dashed red line, materializing the neck location, and iso-height lines in figure 3(a). Here, the radial and upwards motion of the neck allows us to distinguish the superheated from the isothermal case where the neck has a fixed radial position and height (Kolinski et al. Reference Kolinski, Rubinstein, Mandre, Brenner, Weitz and Mahadevan2012, Reference Kolinski, Mahadevan and Rubinstein2014b).

$r=0$) is constant, as evidenced by the absence of crossings between iso-height lines (i.e. fringes) and the centreline in figure 3(a). In the same time interval, the neck thickness increases, as shown by the TIR data (figure 3b) and by the multiple crossings between the dashed red line, materializing the neck location, and iso-height lines in figure 3(a). Here, the radial and upwards motion of the neck allows us to distinguish the superheated from the isothermal case where the neck has a fixed radial position and height (Kolinski et al. Reference Kolinski, Rubinstein, Mandre, Brenner, Weitz and Mahadevan2012, Reference Kolinski, Mahadevan and Rubinstein2014b).(iii) In the final phase (

$t>0.4$ ms), both the thickness at the centre and at the neck increase as the liquid keeps spreading. This global film thickness increase, which occurs at different instants at the neck and at the dimple, further differentiates the hot and the cold case and is characteristic of the influence of vapour generation.

$t>0.4$ ms), both the thickness at the centre and at the neck increase as the liquid keeps spreading. This global film thickness increase, which occurs at different instants at the neck and at the dimple, further differentiates the hot and the cold case and is characteristic of the influence of vapour generation.

Figure 3. (a,b) Space–time plots of the short-time film dynamics obtained by azimuthally averaging the RI and TIR snapshots for the impact shown in figure 2(a) (![]() $R = 1.1$ mm,

$R = 1.1$ mm, ![]() $U = 0.5$ m s

$U = 0.5$ m s![]() $^{-1}$,

$^{-1}$, ![]() ${\textit {We}} = 9.9$ and

${\textit {We}} = 9.9$ and ![]() $T_s = 164\,^\circ$C). The dashed lines in (a,b) and (d,e) are a guide to the eye indicating the position of the neck extracted from the RI space–time plots. (c) Successive liquid–gas profiles extracted from (b). The colour code stands for the time difference from the instant at which the minimum thickness is reached. (d,e) Space–time plots obtained for similar impact parameters as in (a,b) (

$T_s = 164\,^\circ$C). The dashed lines in (a,b) and (d,e) are a guide to the eye indicating the position of the neck extracted from the RI space–time plots. (c) Successive liquid–gas profiles extracted from (b). The colour code stands for the time difference from the instant at which the minimum thickness is reached. (d,e) Space–time plots obtained for similar impact parameters as in (a,b) (![]() $R = 1.0$ mm,

$R = 1.0$ mm, ![]() $U = 0.48$ m s

$U = 0.48$ m s![]() $^{-1}$ and

$^{-1}$ and ![]() ${\textit {We}} = 8.3$) but with

${\textit {We}} = 8.3$) but with ![]() $T_s = 105\,^\circ$C. ( f) Successive height profiles extracted from (e). The colour code is the same as in (c). Video (S3) is available in the supplementary material.

$T_s = 105\,^\circ$C. ( f) Successive height profiles extracted from (e). The colour code is the same as in (c). Video (S3) is available in the supplementary material.

3.1.2. Recovering the isothermal behaviour

We observe the transition from the superheated to the isothermal behaviour by performing impacts on substrates heated just above the boiling temperature of ethanol. For similar impact parameters as in figure 2(a) (![]() $U = 0.48$ m s

$U = 0.48$ m s![]() $^{-1}$,

$^{-1}$, ![]() ${\textit {We}} = 8.3$) but with

${\textit {We}} = 8.3$) but with ![]() $T_s = 105\,^\circ$C, the liquid–gas interface transiently forms a wide flat region that is closer to the substrate (figure 3e), while the dimple shape remains frozen, as shown by the horizontal fringes in figure 3(d): we recover the film shape reported for isothermal conditions (Kolinski et al. Reference Kolinski, Mahadevan and Rubinstein2014b). The collapse of the successive height profiles at the neck region plotted in figure 3( f) illustrates the transition from a neck sweeping motion (figure 3c) to a quasi-invariant film shape with decreasing superheat. The growth of the thickness at the neck and, later, at the centre indicates that vapour is still generated and distinguishes this case from the isothermal impact.

$T_s = 105\,^\circ$C, the liquid–gas interface transiently forms a wide flat region that is closer to the substrate (figure 3e), while the dimple shape remains frozen, as shown by the horizontal fringes in figure 3(d): we recover the film shape reported for isothermal conditions (Kolinski et al. Reference Kolinski, Mahadevan and Rubinstein2014b). The collapse of the successive height profiles at the neck region plotted in figure 3( f) illustrates the transition from a neck sweeping motion (figure 3c) to a quasi-invariant film shape with decreasing superheat. The growth of the thickness at the neck and, later, at the centre indicates that vapour is still generated and distinguishes this case from the isothermal impact.

We now seek to quantitatively characterize the effect of the superheat on the gas layer. To do so, we describe the neck motion and measure the film thickness at the neck and at the centre, when there is no liquid–solid contact at short time, for different superheats and impact velocities.

3.2. Neck dynamics

We track the azimuthally averaged neck radius ![]() $r_n(t)$ (figure 4a) and distance to the substrate (i.e. neck height)

$r_n(t)$ (figure 4a) and distance to the substrate (i.e. neck height) ![]() $h_n(t) = h(r_n(t),t)$ (figure 4b) for varying impact velocities and substrate temperatures at short times. As the neck spreads, its height decreases, with a velocity

$h_n(t) = h(r_n(t),t)$ (figure 4b) for varying impact velocities and substrate temperatures at short times. As the neck spreads, its height decreases, with a velocity ![]() $\textrm {d} h_n/\textrm {d} t$ of the order of the impact velocity, until it reaches a minimum value

$\textrm {d} h_n/\textrm {d} t$ of the order of the impact velocity, until it reaches a minimum value ![]() $h_m$ that corresponds to the global minimum of the azimuthally averaged gas layer thickness. Later, the neck height grows at a slower rate. The evolution of

$h_m$ that corresponds to the global minimum of the azimuthally averaged gas layer thickness. Later, the neck height grows at a slower rate. The evolution of ![]() $r_n(t)$ seems to be only affected by the impact velocity. In contrast, the neck height

$r_n(t)$ seems to be only affected by the impact velocity. In contrast, the neck height ![]() $h_n(t)$ is strongly influenced also by the substrate temperature

$h_n(t)$ is strongly influenced also by the substrate temperature ![]() $T_s$. This behaviour suggests that the spreading dynamics evidenced for isothermal impacts (Rioboo, Marengo & Tropea Reference Rioboo, Marengo and Tropea2002; Mongruel et al. Reference Mongruel, Daru, Feuillebois and Tabakova2009; Thoroddsen, Takehara & Etoh Reference Thoroddsen, Takehara and Etoh2012) could describe the neck motion. Notably, the Wagner prediction,

$T_s$. This behaviour suggests that the spreading dynamics evidenced for isothermal impacts (Rioboo, Marengo & Tropea Reference Rioboo, Marengo and Tropea2002; Mongruel et al. Reference Mongruel, Daru, Feuillebois and Tabakova2009; Thoroddsen, Takehara & Etoh Reference Thoroddsen, Takehara and Etoh2012) could describe the neck motion. Notably, the Wagner prediction, ![]() $r_n(t) = \sqrt {3URt}$, shown to be accurate for the radius of the liquid–solid contact by Riboux & Gordillo (Reference Riboux and Gordillo2014) and Gordillo et al. (Reference Gordillo, Riboux and Quintero2019) on cold surfaces and by Shirota et al. (Reference Shirota, van Limbeek, Sun, Prosperetti and Lohse2016) on superheated substrates, could also be relevant in the levitated regime. We indeed observe a good agreement of that prediction with the data by plotting the normalized neck radius

$r_n(t) = \sqrt {3URt}$, shown to be accurate for the radius of the liquid–solid contact by Riboux & Gordillo (Reference Riboux and Gordillo2014) and Gordillo et al. (Reference Gordillo, Riboux and Quintero2019) on cold surfaces and by Shirota et al. (Reference Shirota, van Limbeek, Sun, Prosperetti and Lohse2016) on superheated substrates, could also be relevant in the levitated regime. We indeed observe a good agreement of that prediction with the data by plotting the normalized neck radius ![]() $r_n/R$ as a function of the dimensionless time

$r_n/R$ as a function of the dimensionless time ![]() $tU/R$ for three different impact velocities and superheats (figure 4c). The data collapse, in quantitative agreement with Wagner's prediction represented by the solid line. We conclude that vapour generation strongly affects the vertical motion of the liquid–gas interface at the neck, but has negligible influence on its horizontal dynamics.

$tU/R$ for three different impact velocities and superheats (figure 4c). The data collapse, in quantitative agreement with Wagner's prediction represented by the solid line. We conclude that vapour generation strongly affects the vertical motion of the liquid–gas interface at the neck, but has negligible influence on its horizontal dynamics.

Figure 4. (a) Time evolution of the azimuthally averaged neck radius ![]() $r_n(t)$ for varying impact velocities

$r_n(t)$ for varying impact velocities ![]() $U$ and substrate temperatures

$U$ and substrate temperatures ![]() $T_s$. The data are extracted from TIR images such as figure 3(b). The solid lines represent predictions from the Wagner theory,

$T_s$. The data are extracted from TIR images such as figure 3(b). The solid lines represent predictions from the Wagner theory, ![]() $r_n(t) = \sqrt {3URt}$. (b) Azimuthally averaged height at the neck

$r_n(t) = \sqrt {3URt}$. (b) Azimuthally averaged height at the neck ![]() $h_n(t)$ at short time. We denote

$h_n(t)$ at short time. We denote ![]() $h_m$ the azimuthally averaged minimum film thickness. (c) Normalized azimuthally averaged neck radius

$h_m$ the azimuthally averaged minimum film thickness. (c) Normalized azimuthally averaged neck radius ![]() $r_n/R$ as a function of the dimensionless time

$r_n/R$ as a function of the dimensionless time ![]() $tU/R$. The solid line shows the Wagner prediction. (d) Central dimple height

$tU/R$. The solid line shows the Wagner prediction. (d) Central dimple height ![]() $h_d$ plotted as a function of

$h_d$ plotted as a function of ![]() $U$ for the impact of drops for various

$U$ for the impact of drops for various ![]() $T_s$. Note that

$T_s$. Note that ![]() $h_d$ has a non-monotonic dependence on

$h_d$ has a non-monotonic dependence on ![]() $T_s$. The solid line corresponds to the scaling

$T_s$. The solid line corresponds to the scaling ![]() $h_d/R \sim {\textit {St}}^{-2/3}$, taking the viscosity of the gas,

$h_d/R \sim {\textit {St}}^{-2/3}$, taking the viscosity of the gas, ![]() $\eta _{g}$, as the viscosity of air at 20

$\eta _{g}$, as the viscosity of air at 20 ![]() $^\circ$C. The dashed and dotted lines correspond to two limiting choices for the gas viscosity, that of air at 230

$^\circ$C. The dashed and dotted lines correspond to two limiting choices for the gas viscosity, that of air at 230 ![]() $^\circ$C, and that of ethanol vapour at

$^\circ$C, and that of ethanol vapour at ![]() $T_b$, respectively. The square symbols are obtained in cases in which the liquid touches the solid. (e) Minimum film thickness

$T_b$, respectively. The square symbols are obtained in cases in which the liquid touches the solid. (e) Minimum film thickness ![]() $h_m$ as a function of the impact speed

$h_m$ as a function of the impact speed ![]() $U$ for various

$U$ for various ![]() $T_s$. The dashed lines are guides to the eye with a slope of

$T_s$. The dashed lines are guides to the eye with a slope of ![]() $-2$. ( f) Normalized minimum film thickness

$-2$. ( f) Normalized minimum film thickness ![]() $h_m/R$ as a function of the prediction of (3.21), the data are consistent with this prediction and a fit gives a prefactor of

$h_m/R$ as a function of the prediction of (3.21), the data are consistent with this prediction and a fit gives a prefactor of ![]() $4.0 \pm 0.2$ in (3.21).

$4.0 \pm 0.2$ in (3.21).

3.3. Thickness at the dimple and the neck

We now focus on the effect of ![]() $T_s$ on the thickness of the gas film. In figure 4(d), we show the dimple height

$T_s$ on the thickness of the gas film. In figure 4(d), we show the dimple height ![]() $h_d$ measured at the same instant as the minimum thickness

$h_d$ measured at the same instant as the minimum thickness ![]() $h_m$ is reached and, for the two lowest substrate temperatures, also at the instant when contact occurs at the neck (square markers), enabling us to probe velocities up to 2 m s

$h_m$ is reached and, for the two lowest substrate temperatures, also at the instant when contact occurs at the neck (square markers), enabling us to probe velocities up to 2 m s![]() $^{-1}$. We obtain

$^{-1}$. We obtain ![]() $h_d$ as the sum of the thickness at the neck

$h_d$ as the sum of the thickness at the neck ![]() $h_m$, determined using TIR, and of the height difference between the dimple and the neck, which we extract from the RI monochromatic fringe pattern. Coupling these two techniques, we are not limited by the 800 nm cutoff height and observe dimple heights of the order of 1 to 5

$h_m$, determined using TIR, and of the height difference between the dimple and the neck, which we extract from the RI monochromatic fringe pattern. Coupling these two techniques, we are not limited by the 800 nm cutoff height and observe dimple heights of the order of 1 to 5 ![]() $\mathrm {\mu }$m, decreasing with increasing impact velocity. We compare our measurements with the scaling relation for

$\mathrm {\mu }$m, decreasing with increasing impact velocity. We compare our measurements with the scaling relation for ![]() $h_d$ derived in the absence of heating,

$h_d$ derived in the absence of heating, ![]() $h_d/R \sim {\textit {St}}^{-2/3}$, where

$h_d/R \sim {\textit {St}}^{-2/3}$, where ![]() ${\textit {St}} = \rho _lRU/\eta _g$ is the Stokes number (Mandre et al. Reference Mandre, Mani and Brenner2009; Mani et al. Reference Mani, Mandre and Brenner2010; Bouwhuis et al. Reference Bouwhuis, van der Veen, Tran, Keij, Winkels, Peters, van der Meer, Sun, Snoeijer and Lohse2012), and

${\textit {St}} = \rho _lRU/\eta _g$ is the Stokes number (Mandre et al. Reference Mandre, Mani and Brenner2009; Mani et al. Reference Mani, Mandre and Brenner2010; Bouwhuis et al. Reference Bouwhuis, van der Veen, Tran, Keij, Winkels, Peters, van der Meer, Sun, Snoeijer and Lohse2012), and ![]() $\eta _g$ the viscosity of the gas layer. Note that we define the Stokes number as the inverse of that proposed by Mandre et al. (Reference Mandre, Mani and Brenner2009) but consistent with other publications on the subject. The data are compatible with the isothermal scaling: for a fixed superheat

$\eta _g$ the viscosity of the gas layer. Note that we define the Stokes number as the inverse of that proposed by Mandre et al. (Reference Mandre, Mani and Brenner2009) but consistent with other publications on the subject. The data are compatible with the isothermal scaling: for a fixed superheat ![]() $\Delta T$ and drop radius

$\Delta T$ and drop radius ![]() $R$, the dimple height decrease with increasing impact velocity

$R$, the dimple height decrease with increasing impact velocity ![]() $U$ is consistent with a power-law behaviour with an exponent

$U$ is consistent with a power-law behaviour with an exponent ![]() $-2/3$. Yet, we observe a weak influence of the substrate temperature on

$-2/3$. Yet, we observe a weak influence of the substrate temperature on ![]() $h_d$ that has a non-monotonic dependence with increasing superheat.

$h_d$ that has a non-monotonic dependence with increasing superheat.

In figure 4(e), we show the minimum distance ![]() $h_m$ separating the drop from the substrate as a function of the control parameters

$h_m$ separating the drop from the substrate as a function of the control parameters ![]() $U$ and

$U$ and ![]() $T_s$. This minimum distance is of the order of a few hundred nanometres, and strongly increases with the superheat, in contrast to the weak non-monotonic influence observed for

$T_s$. This minimum distance is of the order of a few hundred nanometres, and strongly increases with the superheat, in contrast to the weak non-monotonic influence observed for ![]() $h_d$. For example, increasing

$h_d$. For example, increasing ![]() $T_s$ from 178 to 230

$T_s$ from 178 to 230 ![]() $^\circ$C leads to a doubling of the thickness at the neck for

$^\circ$C leads to a doubling of the thickness at the neck for ![]() $U = 0.7$ m s

$U = 0.7$ m s![]() $^{-1}$. For a fixed substrate temperature and drop radius, the data suggest a power-law decrease of

$^{-1}$. For a fixed substrate temperature and drop radius, the data suggest a power-law decrease of ![]() $h_m$ with the impact velocity

$h_m$ with the impact velocity ![]() $U$ with an exponent

$U$ with an exponent ![]() $-2 \pm 0.2$. This exponent is close to that predicted for the minimum thickness at the neck in the isothermal case

$-2 \pm 0.2$. This exponent is close to that predicted for the minimum thickness at the neck in the isothermal case ![]() $-20/9$ (Mandre et al. Reference Mandre, Mani and Brenner2009; Mani et al. Reference Mani, Mandre and Brenner2010), but the strong influence of

$-20/9$ (Mandre et al. Reference Mandre, Mani and Brenner2009; Mani et al. Reference Mani, Mandre and Brenner2010), but the strong influence of ![]() $\Delta T$ evidences the role of evaporation and distinguishes this case from an impact on a substrate at ambient temperature .

$\Delta T$ evidences the role of evaporation and distinguishes this case from an impact on a substrate at ambient temperature .

3.4. Model for the initial approach

We now seek to model the initial approach, i.e. the evolution of the gas film until the minimum thickness is reached at the neck. Typically, this phase lasts until ![]() $tU/R < 0.01$, a time much shorter than that associated with the purely inertial spreading that is valid up to

$tU/R < 0.01$, a time much shorter than that associated with the purely inertial spreading that is valid up to ![]() $tU/R < 0.1$. We build on the work of Mani et al. (Reference Mani, Mandre and Brenner2010), who treated the case of isothermal impacts, and extend it to take into account the effect of vapour production. Indeed, our measurements of the dimple thickness in superheated conditions show the same scaling relation with the Stokes number as for isothermal impacts, indicating that liquid inertia and viscous drainage are still the relevant mechanisms when the substrate is heated. Yet, the thickness at the neck strongly depends on the superheat, suggesting that, to describe the movement of the liquid–gas interface, one also needs to capture the influence of vapour generation.

$tU/R < 0.1$. We build on the work of Mani et al. (Reference Mani, Mandre and Brenner2010), who treated the case of isothermal impacts, and extend it to take into account the effect of vapour production. Indeed, our measurements of the dimple thickness in superheated conditions show the same scaling relation with the Stokes number as for isothermal impacts, indicating that liquid inertia and viscous drainage are still the relevant mechanisms when the substrate is heated. Yet, the thickness at the neck strongly depends on the superheat, suggesting that, to describe the movement of the liquid–gas interface, one also needs to capture the influence of vapour generation.

For completeness, we reproduce the equations of motion for the liquid and for the gas film in the incompressible regime as already derived by Mani et al. (Reference Mani, Mandre and Brenner2010). Following them, we consider a two-dimensional geometry and make further simplifications as in the isothermal case: in the liquid, we neglect viscosity and nonlinear inertia owing to, respectively, the large Reynolds number (![]() ${\textit {Re}} = \rho _l R U/\eta _l = 330$ for the impact of a millimetre-sized drop at

${\textit {Re}} = \rho _l R U/\eta _l = 330$ for the impact of a millimetre-sized drop at ![]() $U = 0.5$ m s

$U = 0.5$ m s![]() $^{-1}$) and the absence of velocity gradients within the drop before it interacts with the substrate. We also neglect the influence of surface tension, as for a typical impact the Weber number,

$^{-1}$) and the absence of velocity gradients within the drop before it interacts with the substrate. We also neglect the influence of surface tension, as for a typical impact the Weber number, ![]() ${\textit {We}} \approx 10$, is considerably larger than unity. With these assumptions, we have potential flow in the liquid and the equation of motion reads

${\textit {We}} \approx 10$, is considerably larger than unity. With these assumptions, we have potential flow in the liquid and the equation of motion reads

where ![]() $\boldsymbol {u} = (u,v)$ are the liquid velocity components in the

$\boldsymbol {u} = (u,v)$ are the liquid velocity components in the ![]() $x$ (replacing

$x$ (replacing ![]() $r$ in this two-dimensional model) and

$r$ in this two-dimensional model) and ![]() $z$ directions, respectively, and

$z$ directions, respectively, and ![]() $p_l$ is the liquid pressure. Projecting (3.1a,b) in the vertical direction and using the kinematic boundary condition at the liquid–gas interface

$p_l$ is the liquid pressure. Projecting (3.1a,b) in the vertical direction and using the kinematic boundary condition at the liquid–gas interface ![]() $\partial h/\partial t = v - u \partial h/\partial x$, we obtain at

$\partial h/\partial t = v - u \partial h/\partial x$, we obtain at ![]() $z=0$

$z=0$

where, in the spirit of the boundary layer approximation (Prandtl Reference Prandtl1904), the term on the right-hand side can be neglected. Then, the vertical pressure gradient at the interface can be expressed as the Hilbert transform of the horizontal pressure gradient by taking advantage of the two-dimensional nature of the problem and the harmonic pressure field (Smith, Li & Wu Reference Smith, Li and Wu2003)

We now come to the description of the gas flow between the drop and the substrate. Here, the viscous lubrication approximation is justified as the gas film is thin (![]() $h \ll R$) and the typical value of the Reynolds number is low in the gas phase (

$h \ll R$) and the typical value of the Reynolds number is low in the gas phase (![]() ${\textit {Re}} = \rho _g h_d U/\eta _g = 0.05$ for air at 20

${\textit {Re}} = \rho _g h_d U/\eta _g = 0.05$ for air at 20 ![]() $^\circ$C). This approximation is valid when considering heating as the value of the Reynolds number is not significantly altered by the presence of ethanol vapour (

$^\circ$C). This approximation is valid when considering heating as the value of the Reynolds number is not significantly altered by the presence of ethanol vapour (![]() ${\textit {Re}} = \rho _v h_d U/\eta _v = 0.15$ for ethanol vapor at

${\textit {Re}} = \rho _v h_d U/\eta _v = 0.15$ for ethanol vapor at ![]() $T_b$), nor by the dependence of the gas viscosity and density on temperature. With these assumptions, we obtain the lubrication equation

$T_b$), nor by the dependence of the gas viscosity and density on temperature. With these assumptions, we obtain the lubrication equation

where ![]() $\xi$ is a numerical coefficient which accounts for the choice of boundary condition at the liquid–gas interface. If the no-slip condition holds at the interface,

$\xi$ is a numerical coefficient which accounts for the choice of boundary condition at the liquid–gas interface. If the no-slip condition holds at the interface, ![]() $\xi = 1$. In contrast, if a zero tangential stress condition is chosen,

$\xi = 1$. In contrast, if a zero tangential stress condition is chosen, ![]() $\xi =4$ (Guyon, Hulin & Petit Reference Guyon, Hulin and Petit2012).

$\xi =4$ (Guyon, Hulin & Petit Reference Guyon, Hulin and Petit2012).

We now introduce an additional term in the lubrication equation to take into account the effect of evaporation. We consider that heat is transferred through the gas layer by conduction, similarly as in the static Leidenfrost situation, as this mechanism acts on a relevant time scale for impact, ![]() $h^2/\kappa _v \approx 0.1\,\mathrm {\mu }$s, much shorter than the initial approach time. The energy input from the heated solid is used to heat liquid at the bottom interface from the ambient temperature

$h^2/\kappa _v \approx 0.1\,\mathrm {\mu }$s, much shorter than the initial approach time. The energy input from the heated solid is used to heat liquid at the bottom interface from the ambient temperature ![]() $T_a$ to the boiling temperature

$T_a$ to the boiling temperature ![]() $T_b$, creating a thermal boundary layer with thickness

$T_b$, creating a thermal boundary layer with thickness ![]() $\sqrt {\kappa _l t}$, and to vaporize it. The Jakob number

$\sqrt {\kappa _l t}$, and to vaporize it. The Jakob number ![]() $Ja = C_{p,l}(T_b - T_a)/\mathcal {L}$, which compares the sensible heat with the latent heat

$Ja = C_{p,l}(T_b - T_a)/\mathcal {L}$, which compares the sensible heat with the latent heat ![]() $\mathcal {L}$, is

$\mathcal {L}$, is ![]() $0.16$ so that we consider the energetic cost coming from the latent heat to be dominant. With this assumption, which overestimates the vapour production, the evaporation rate per unit area,

$0.16$ so that we consider the energetic cost coming from the latent heat to be dominant. With this assumption, which overestimates the vapour production, the evaporation rate per unit area, ![]() $e$, is given by balancing the heat flux

$e$, is given by balancing the heat flux ![]() $k_g\Delta T/h$ with the released latent heat

$k_g\Delta T/h$ with the released latent heat ![]() $\mathcal {L}e$, yielding

$\mathcal {L}e$, yielding ![]() $e = k_g\Delta T/(\mathcal {L}h)$. We thus obtain a modified lubrication equation

$e = k_g\Delta T/(\mathcal {L}h)$. We thus obtain a modified lubrication equation

where the term on the right-hand side takes into account evaporation (Biance, Clanet & Quéré Reference Biance, Clanet and Quéré2003; Sobac et al. Reference Sobac, Rednikov, Dorbolo and Colinet2014).

3.4.1. Dimple height

Having obtained the governing equations for the liquid and the gas, we recall the dimple height scaling derived for isothermal impacts (Mani et al. Reference Mani, Mandre and Brenner2010; Bouwhuis et al. Reference Bouwhuis, van der Veen, Tran, Keij, Winkels, Peters, van der Meer, Sun, Snoeijer and Lohse2012). It is obtained by balancing liquid inertia with viscous drainage in the squeezed gas film. The pressure in the liquid can be estimated from (3.2) or (3.3)

where ![]() $L \sim \sqrt {h_dR}$ is the radial extent of the dimple computed as the radius of a spherical cap with height

$L \sim \sqrt {h_dR}$ is the radial extent of the dimple computed as the radius of a spherical cap with height ![]() $h_d$. The gas pressure is deduced from the two-dimensional incompressible lubrication equation (3.4)

$h_d$. The gas pressure is deduced from the two-dimensional incompressible lubrication equation (3.4)

The dimple height is set when the liquid–gas interface first deforms, that is when the pressure in the liquid and in the gas become comparable

\begin{equation} h_d \sim R\left(\frac{\eta_g}{\rho_lRU}\right)^{2/3} \sim R {\textit{St}}^{{-}2/3}, \end{equation}

\begin{equation} h_d \sim R\left(\frac{\eta_g}{\rho_lRU}\right)^{2/3} \sim R {\textit{St}}^{{-}2/3}, \end{equation}

where ![]() ${\textit {St}} = \rho _lRU/\eta _g$ is the Stokes number. The solid line (figure 4d) represents (3.8) with

${\textit {St}} = \rho _lRU/\eta _g$ is the Stokes number. The solid line (figure 4d) represents (3.8) with ![]() $\eta _g$ taken as the viscosity of air at 20

$\eta _g$ taken as the viscosity of air at 20 ![]() $^\circ$C and a prefactor of 2.8 extracted from the results of Bouwhuis et al. (Reference Bouwhuis, van der Veen, Tran, Keij, Winkels, Peters, van der Meer, Sun, Snoeijer and Lohse2012) for the impact of ethanol drops on a substrate at room temperature. The isothermal scaling gives a correct order of magnitude of

$^\circ$C and a prefactor of 2.8 extracted from the results of Bouwhuis et al. (Reference Bouwhuis, van der Veen, Tran, Keij, Winkels, Peters, van der Meer, Sun, Snoeijer and Lohse2012) for the impact of ethanol drops on a substrate at room temperature. The isothermal scaling gives a correct order of magnitude of ![]() $h_d$ and recovers the velocity dependence in superheated conditions, confirming that the viscous drainage of the gas layer dominates vapour generation as suggested by the weak influence of substrate temperature on the dimple height in our experiments.

$h_d$ and recovers the velocity dependence in superheated conditions, confirming that the viscous drainage of the gas layer dominates vapour generation as suggested by the weak influence of substrate temperature on the dimple height in our experiments.

We propose to explain the observed influence of ![]() $T_s$ also through (3.8), although it does not explicitly involve temperature. Indeed,

$T_s$ also through (3.8), although it does not explicitly involve temperature. Indeed, ![]() $\eta _g$ depends on temperature in two ways. (i) The viscosity of the air squeezed between the drop and the surface increases with

$\eta _g$ depends on temperature in two ways. (i) The viscosity of the air squeezed between the drop and the surface increases with ![]() $T_s$, and (ii) as ethanol vapour is generated, the squeezed layer becomes a – possibly non-homogeneous – mixture of warm air and ethanol vapour, whose viscosity is lower than that of air at the same temperature. The interplay between these two antagonistic effects could be the cause of the non-monotonic behaviour of

$T_s$, and (ii) as ethanol vapour is generated, the squeezed layer becomes a – possibly non-homogeneous – mixture of warm air and ethanol vapour, whose viscosity is lower than that of air at the same temperature. The interplay between these two antagonistic effects could be the cause of the non-monotonic behaviour of ![]() $h_d$ with

$h_d$ with ![]() $T_s$. In figure 4(d), we plot the scalings associated with each effect by taking

$T_s$. In figure 4(d), we plot the scalings associated with each effect by taking ![]() $\eta _g$ as the viscosity of air at 230

$\eta _g$ as the viscosity of air at 230 ![]() $^\circ$C (dashed line) and as the viscosity of ethanol vapour at the boiling point (dotted line): all measurements lie in between the two bounds.

$^\circ$C (dashed line) and as the viscosity of ethanol vapour at the boiling point (dotted line): all measurements lie in between the two bounds.

3.4.2. Neck thickness

We next focus on the subsequent formation of the neck. Here, we extend the calculation of Mani et al. (Reference Mani, Mandre and Brenner2010) to incorporate the effect of evaporation, as our experimental observations show a strong influence of the substrate temperature on the thickness at the neck. We non-dimensionalize the governing equations (3.3) and (3.5) with the scales involved in the dimple formation, namely with the transformations

where ![]() $P_0$ is the atmospheric pressure. Then, the equations of motion of the liquid and gas respectively become

$P_0$ is the atmospheric pressure. Then, the equations of motion of the liquid and gas respectively become

Here, we have introduced two extra dimensionless quantities:

(i) the ratio of the atmospheric pressure to the pressure build-up below the drop,

(3.12) \begin{equation} \delta = \frac{P_0 RSt^{{-}4/3}}{\eta_gU}; \end{equation}

\begin{equation} \delta = \frac{P_0 RSt^{{-}4/3}}{\eta_gU}; \end{equation}(ii) and the evaporation number

$\mathcal {E}$ defined by Sobac et al. (Reference Sobac, Rednikov, Dorbolo and Colinet2014) in the study of static Leidenfrost drops,

(3.13)

$\mathcal {E}$ defined by Sobac et al. (Reference Sobac, Rednikov, Dorbolo and Colinet2014) in the study of static Leidenfrost drops,

(3.13) \begin{equation} \mathcal{E} = \frac{\eta_g k_g \Delta T}{\gamma \rho_g R \mathcal{L}}. \end{equation}

\begin{equation} \mathcal{E} = \frac{\eta_g k_g \Delta T}{\gamma \rho_g R \mathcal{L}}. \end{equation}

The pressure buildup in the gas film below the drop is a small correction to the atmospheric pressure. We thus consider the limit ![]() $\delta \gg 1$, that is the incompressible limit, and assume the following pressure expansion

$\delta \gg 1$, that is the incompressible limit, and assume the following pressure expansion ![]() $\tilde {p}_g = 1 + \tilde {p}/\delta$ which we introduce in the governing equation:

$\tilde {p}_g = 1 + \tilde {p}/\delta$ which we introduce in the governing equation:

where we used the pressure continuity at the interface (i.e. ![]() $p_g = p_l$). As the motion of the liquid–gas interface is similar in the isothermal and the superheated cases, we adopt the same self-similar ansatz as in Mani et al. (Reference Mani, Mandre and Brenner2010) and construct a self-similar solution for the behaviour in the neck region. The height and the pressure are given by

$p_g = p_l$). As the motion of the liquid–gas interface is similar in the isothermal and the superheated cases, we adopt the same self-similar ansatz as in Mani et al. (Reference Mani, Mandre and Brenner2010) and construct a self-similar solution for the behaviour in the neck region. The height and the pressure are given by

where ![]() $\varTheta (\tilde {x},\tilde {t}) = (\tilde {x}-\tilde {x}_n(\tilde {t}))/\widetilde {\ell }(\tilde {t})$ is the self-similarity variable,

$\varTheta (\tilde {x},\tilde {t}) = (\tilde {x}-\tilde {x}_n(\tilde {t}))/\widetilde {\ell }(\tilde {t})$ is the self-similarity variable, ![]() $\tilde {x}_n(\tilde {t})$ the neck's radial coordinate,

$\tilde {x}_n(\tilde {t})$ the neck's radial coordinate, ![]() $\tilde {p}_n(\tilde {t})$ the pressure at

$\tilde {p}_n(\tilde {t})$ the pressure at ![]() $\tilde {x} = \tilde {x}_n(\tilde {t})$ and

$\tilde {x} = \tilde {x}_n(\tilde {t})$ and ![]() $\widetilde {\ell }(\tilde {t})$ the horizontal length scale associated with the high-curvature region, i.e. the neck region. The time derivatives of the height or pressure field have three contributions coming respectively from the height's temporal variation, the change of horizontal extent, and the radial motion of the neck

$\widetilde {\ell }(\tilde {t})$ the horizontal length scale associated with the high-curvature region, i.e. the neck region. The time derivatives of the height or pressure field have three contributions coming respectively from the height's temporal variation, the change of horizontal extent, and the radial motion of the neck

Mani et al. (Reference Mani, Mandre and Brenner2010) hypothesized that the advection term is dominant and proposed that the neck region has a wave-like behaviour: ![]() $\textrm {d}/\textrm {d}\tilde {t} \approx \tilde {c} \textrm {d}/\textrm {d}\tilde {x}$ where

$\textrm {d}/\textrm {d}\tilde {t} \approx \tilde {c} \textrm {d}/\textrm {d}\tilde {x}$ where ![]() $\tilde {c} = \textrm {d} \tilde {x}_n/\textrm {d}\tilde {t}$ is the neck radial velocity that is considered to be constant during the initial approach. This hypothesis seems to be at odds with our description of the neck dynamics using Wagner theory where

$\tilde {c} = \textrm {d} \tilde {x}_n/\textrm {d}\tilde {t}$ is the neck radial velocity that is considered to be constant during the initial approach. This hypothesis seems to be at odds with our description of the neck dynamics using Wagner theory where ![]() $x_n$ evolves as

$x_n$ evolves as ![]() $\sqrt {t}$. This apparent contradiction can be resolved by comparing the time scales associated with the initial approach phase and the motion captured by Wagner's theory. Typically, the minimum thickness is reached for

$\sqrt {t}$. This apparent contradiction can be resolved by comparing the time scales associated with the initial approach phase and the motion captured by Wagner's theory. Typically, the minimum thickness is reached for ![]() $tU/R < 0.01$ while Wagner's theory is valid up to dimensionless times of the order of

$tU/R < 0.01$ while Wagner's theory is valid up to dimensionless times of the order of ![]() $0.1$. This separation of time scales validates the use of a linear approximation for the neck position during the initial approach. Introducing the self-similar fields in (3.14a,b) and using the wave like nature of the solution we obtain

$0.1$. This separation of time scales validates the use of a linear approximation for the neck position during the initial approach. Introducing the self-similar fields in (3.14a,b) and using the wave like nature of the solution we obtain

This set of equations is identical to that obtained by Mani et al. (Reference Mani, Mandre and Brenner2010) in the isothermal case except for the additional term on the right hand side of (3.18) that incorporates the influence of evaporation in the viscous lubrication flow.

If the liquid's latent heat tends towards infinity or no superheat is applied, the evaporation number ![]() $\mathcal {E}$ tends towards zero and the terms on the left-hand side balance as in the isothermal case (see Mani et al. (Reference Mani, Mandre and Brenner2010) and Appendix C). On the contrary, if evaporation plays a dominant role as suggested by the strong influence of superheat on the minimum thickness at the neck, the evaporation term balances the downwards motion of the interface (the first term in (3.18)). Equation (3.18) then gives a relationship between the horizontal and the vertical length scales

$\mathcal {E}$ tends towards zero and the terms on the left-hand side balance as in the isothermal case (see Mani et al. (Reference Mani, Mandre and Brenner2010) and Appendix C). On the contrary, if evaporation plays a dominant role as suggested by the strong influence of superheat on the minimum thickness at the neck, the evaporation term balances the downwards motion of the interface (the first term in (3.18)). Equation (3.18) then gives a relationship between the horizontal and the vertical length scales

that we combine with the scaling extracted from (3.17), ![]() $\tilde {p}_n \sim \tilde {h}_n \tilde {c}^2/\widetilde {\ell }$, to obtain a relation between the pressure and height at the neck

$\tilde {p}_n \sim \tilde {h}_n \tilde {c}^2/\widetilde {\ell }$, to obtain a relation between the pressure and height at the neck

As ![]() $h_n$ decreases, the initially neglected Laplace pressure at the neck

$h_n$ decreases, the initially neglected Laplace pressure at the neck ![]() $\gamma h_n/\ell ^2$, that scales as

$\gamma h_n/\ell ^2$, that scales as ![]() $h_n^{-3}$, diverges quicker than the gas pressure at the neck

$h_n^{-3}$, diverges quicker than the gas pressure at the neck ![]() $p_n$, that evolves as

$p_n$, that evolves as ![]() $h_n^{-1}$. The hypothesis to neglect surface tension is no longer valid as the drop approaches the solid, similarly as for isothermal impacts. The balance between

$h_n^{-1}$. The hypothesis to neglect surface tension is no longer valid as the drop approaches the solid, similarly as for isothermal impacts. The balance between ![]() $p_n$ and the Laplace pressure sets the minimum film thickness

$p_n$ and the Laplace pressure sets the minimum film thickness ![]() $h_m$

$h_m$

Equation (3.21) predicts a power-law decrease of the minimum thickness as a function of impact velocity ![]() $U$ with an exponent

$U$ with an exponent ![]() $-2$ when fixing the drop radius and superheat, consistent with the experimental findings displayed in figure 4(e), where the dashed lines are guides to the eye with a slope of

$-2$ when fixing the drop radius and superheat, consistent with the experimental findings displayed in figure 4(e), where the dashed lines are guides to the eye with a slope of ![]() $-2$. This power-law decrease,

$-2$. This power-law decrease, ![]() $h_m \propto U^{-2}$, is close to that numerically predicted in the isothermal case where the minimum thickness follows a power law with exponent

$h_m \propto U^{-2}$, is close to that numerically predicted in the isothermal case where the minimum thickness follows a power law with exponent ![]() $-20/9$ (Mani et al. Reference Mani, Mandre and Brenner2010). In Appendix C, we derive this isothermal scaling and show that it does not allow us to capture the effect of substrate temperature, contrary to (3.21) which explicitly involves superheat. Testing the effect of the substrate temperature

$-20/9$ (Mani et al. Reference Mani, Mandre and Brenner2010). In Appendix C, we derive this isothermal scaling and show that it does not allow us to capture the effect of substrate temperature, contrary to (3.21) which explicitly involves superheat. Testing the effect of the substrate temperature ![]() $T_s$ requires us to take into account the temperature-dependent values of the gas viscosity, density and thermal conductivity as well as the value of the liquid surface tension. The viscous effects are introduced by the gas drainage associated with dimple formation. We thus use the temperature-dependent gas viscosity extracted from our measurements of the dimple height. The gas density and thermal conductivity, on the contrary, are related to vapour generation at the neck. Given the conduction time scale

$T_s$ requires us to take into account the temperature-dependent values of the gas viscosity, density and thermal conductivity as well as the value of the liquid surface tension. The viscous effects are introduced by the gas drainage associated with dimple formation. We thus use the temperature-dependent gas viscosity extracted from our measurements of the dimple height. The gas density and thermal conductivity, on the contrary, are related to vapour generation at the neck. Given the conduction time scale ![]() $h^2/\kappa _v\approx 0.1\,\mathrm {\mu }$s, we consider steady heat transfer in the lubrication layer. The temperature profile is linear between the substrate temperature

$h^2/\kappa _v\approx 0.1\,\mathrm {\mu }$s, we consider steady heat transfer in the lubrication layer. The temperature profile is linear between the substrate temperature ![]() $T_s$ and the temperature at the liquid–gas interface where evaporation occurs, that is

$T_s$ and the temperature at the liquid–gas interface where evaporation occurs, that is ![]() $T_b$. We then evaluate the gas density

$T_b$. We then evaluate the gas density ![]() $\rho _g$ and thermal conductivity

$\rho _g$ and thermal conductivity ![]() $k_g$ at

$k_g$ at ![]() $(T_s+T_b)/2$, assuming that the gas phase in the neck region is constituted of ethanol vapour only, and taking the surface tension

$(T_s+T_b)/2$, assuming that the gas phase in the neck region is constituted of ethanol vapour only, and taking the surface tension ![]() $\gamma$ at temperature

$\gamma$ at temperature ![]() $T_b$. In figure 4( f), we compare the normalized minimum thickness

$T_b$. In figure 4( f), we compare the normalized minimum thickness ![]() $h_m/R$ with the prediction of (3.21). The data for different superheats and impact velocities collapse onto a line with prefactor

$h_m/R$ with the prediction of (3.21). The data for different superheats and impact velocities collapse onto a line with prefactor ![]() $4.0\pm 0.2$. This prefactor can be rationalized by coming back on the hypothesis to neglect the subdominant gas drainage contribution to levitation at the neck. This assumption leads us to underestimate the minimum thickness. We thus expect a prefactor larger than one in (3.21), which is consistent with what we see in experiments. The influence of drainage might also explain the deviation from the scaling, observed in figure 4( f) for the largest values of

$4.0\pm 0.2$. This prefactor can be rationalized by coming back on the hypothesis to neglect the subdominant gas drainage contribution to levitation at the neck. This assumption leads us to underestimate the minimum thickness. We thus expect a prefactor larger than one in (3.21), which is consistent with what we see in experiments. The influence of drainage might also explain the deviation from the scaling, observed in figure 4( f) for the largest values of ![]() $We^{-1}\mathcal {E}^{1/2}$, as these discrepancies correspond to the largest thicknesses, for which we expect the relative importance of drainage compared with evaporation to increase.

$We^{-1}\mathcal {E}^{1/2}$, as these discrepancies correspond to the largest thicknesses, for which we expect the relative importance of drainage compared with evaporation to increase.

4. Transition from levitation to contact

As the minimum film thickness decreases with the impact velocity, one expects that, for large enough impact velocities, the liquid wets the solid at short times; an event that indeed occurs. In this section, we report our observations of the collapse of the gas film and discuss the transition from levitation to contact. We first map this transition in the parameter space spanned by surface temperature and impact velocity (figure 5a). We report three distinct types of breakdowns, namely a short-time contact (filled red diamonds), a late-time contact (filled orange dots) and a contact induced by oscillations of the gas film (open red diamonds). We now discuss the phenomenology of these contacts, starting from large velocities in figure 5(a), and then going to lower and lower ones.

Figure 5. (a) Phase diagram of the levitation and contact regimes for ethanol drops in the parameter space spanned by impact velocity ![]() $U$ and substrate temperature

$U$ and substrate temperature ![]() $T_s$. (b) TIR snapshots for an impact with

$T_s$. (b) TIR snapshots for an impact with ![]() $U = 0.76$ m s

$U = 0.76$ m s![]() $^{-1}$,

$^{-1}$, ![]() $R = 1.0$ mm (i.e.

$R = 1.0$ mm (i.e. ![]() ${\textit {We}} = 21$) and

${\textit {We}} = 21$) and ![]() $T_s = 178\,^\circ$C. Contact occurs at short time and we observe a partial wetting pattern (

$T_s = 178\,^\circ$C. Contact occurs at short time and we observe a partial wetting pattern (![]() $t = 0.17$ ms) characteristic of transition or contact boiling. (c) Synchronized side view and TIR images (

$t = 0.17$ ms) characteristic of transition or contact boiling. (c) Synchronized side view and TIR images (![]() $R = 1.0$ mm,

$R = 1.0$ mm, ![]() $U = 0.33$ m s

$U = 0.33$ m s![]() $^{-1}$,

$^{-1}$, ![]() ${\textit {We}} = 3.9$ and

${\textit {We}} = 3.9$ and ![]() $T_s = 105\,^\circ$C) showing late-time contact induced by the jet formed during the retraction process. (d) Space–time RI and TIR plots for an impact with

$T_s = 105\,^\circ$C) showing late-time contact induced by the jet formed during the retraction process. (d) Space–time RI and TIR plots for an impact with ![]() $U = 0.68$ m s

$U = 0.68$ m s![]() $^{-1}$,

$^{-1}$, ![]() $R = 1.0$ mm (i.e.

$R = 1.0$ mm (i.e. ![]() ${\textit {We}} = 17$) and

${\textit {We}} = 17$) and ![]() $T_s = 178\,^\circ$C. Axisymmetric oscillations of the gas film, with frequency

$T_s = 178\,^\circ$C. Axisymmetric oscillations of the gas film, with frequency ![]() $f = 27 \pm 3$ kHz, appear as the central film thickness starts to increase. Their amplitudes eventually decrease and no contact occurs during the whole rebound. Oscillations are not visible using TIR imaging. (e) Space–time plots extracted from RI and TIR for an impact with

$f = 27 \pm 3$ kHz, appear as the central film thickness starts to increase. Their amplitudes eventually decrease and no contact occurs during the whole rebound. Oscillations are not visible using TIR imaging. (e) Space–time plots extracted from RI and TIR for an impact with ![]() $U = 0.78$ m s

$U = 0.78$ m s![]() $^{-1}$,

$^{-1}$, ![]() $R = 1.0$ mm (i.e.

$R = 1.0$ mm (i.e. ![]() ${\textit {We}} = 22$) and

${\textit {We}} = 22$) and ![]() $T_s = 178\,^\circ$C. The oscillations, initially only visible using RI, grow and appear within the evanescent length scale as the interference pattern disappears. ( f) TIR snapshots for the same impact as in (e), showing the growth of oscillations and the creation of a circular contact (

$T_s = 178\,^\circ$C. The oscillations, initially only visible using RI, grow and appear within the evanescent length scale as the interference pattern disappears. ( f) TIR snapshots for the same impact as in (e), showing the growth of oscillations and the creation of a circular contact (![]() $t = 0.5$ ms). Videos (S4–S7) are available in the supplementary material.

$t = 0.5$ ms). Videos (S4–S7) are available in the supplementary material.

4.1. Phenomenology

4.1.1. Short-time contact

We begin by describing the prevalent mode of contact that occurs for all the probed substrate temperatures. Short-time contact is characterized by the occurrence of localized liquid–solid contact at the neck for ![]() $t \ll \tau _i$ (figure 5(b),

$t \ll \tau _i$ (figure 5(b), ![]() $t= 0.031$ ms). As one would expect, the impact velocity

$t= 0.031$ ms). As one would expect, the impact velocity ![]() $U$ above which short-time contact is observed increases with the substrate temperature

$U$ above which short-time contact is observed increases with the substrate temperature ![]() $T_s$ (filled red diamonds, figure 5a). After the contact nucleates, we observe partial wetting patterns typical of transition or contact boiling (

$T_s$ (filled red diamonds, figure 5a). After the contact nucleates, we observe partial wetting patterns typical of transition or contact boiling (![]() $t = 0.098$ and

$t = 0.098$ and ![]() $t= 0.17$ ms), as previously described by Shirota et al. (Reference Shirota, van Limbeek, Sun, Prosperetti and Lohse2016). For moderate impact velocities (

$t= 0.17$ ms), as previously described by Shirota et al. (Reference Shirota, van Limbeek, Sun, Prosperetti and Lohse2016). For moderate impact velocities (![]() $U < 0.8$ m s

$U < 0.8$ m s![]() $^{-1}$, corresponding to

$^{-1}$, corresponding to ![]() ${\textit {We}} = 23$), we have sufficient space and time resolution to determine the film height at the instant before the film collapses (see Appendix D). The thicknesses at rupture are broadly distributed, with an average value of 0.36

${\textit {We}} = 23$), we have sufficient space and time resolution to determine the film height at the instant before the film collapses (see Appendix D). The thicknesses at rupture are broadly distributed, with an average value of 0.36 ![]() $\mathrm {\mu }$m, in agreement with data obtained for isothermal impacts on glass substrates (De Ruiter et al. Reference De Ruiter, Oh, van den Ende and Mugele2012; Kolinski et al. Reference Kolinski, Mahadevan and Rubinstein2014a). Here,

$\mathrm {\mu }$m, in agreement with data obtained for isothermal impacts on glass substrates (De Ruiter et al. Reference De Ruiter, Oh, van den Ende and Mugele2012; Kolinski et al. Reference Kolinski, Mahadevan and Rubinstein2014a). Here, ![]() $h_c$ is typically much larger than the root mean square roughness of the sapphire substrate, or the range of the attractive surface forces, suggesting that surface asperities or contamination play a dominant role in triggering liquid–solid contact. This hypothesis was confirmed by Kolinski et al. (Reference Kolinski, Mahadevan and Rubinstein2014a), who reported similarly distributed rupture thicknesses on all but atomically smooth surfaces, such as freshly cleaved mica, for which they measured nanometric values of

$h_c$ is typically much larger than the root mean square roughness of the sapphire substrate, or the range of the attractive surface forces, suggesting that surface asperities or contamination play a dominant role in triggering liquid–solid contact. This hypothesis was confirmed by Kolinski et al. (Reference Kolinski, Mahadevan and Rubinstein2014a), who reported similarly distributed rupture thicknesses on all but atomically smooth surfaces, such as freshly cleaved mica, for which they measured nanometric values of ![]() $h_c$.

$h_c$.

4.1.2. Late-time contact